Non-Destructive Testing

Rely on our NADCAP-accredited nondestructive testing to analyze your materials for cracks, weld verification, voids and other defects.

- Liquid Penetrant Inspection

- Magnetic Particle (Magnaflux)

- Nital Etch

Coatings

With multiple lines and batch capabilities, Sub Source will meet your unique size, shape and OEM specifications.

- Dry Film Lubricants

- Powder Coating

- Chemical Agent Resistant Coating (CARC) Paint

- Alkyds, Epoxies & Polyurethanes

- Military Spec (MIL-SPEC) Paint

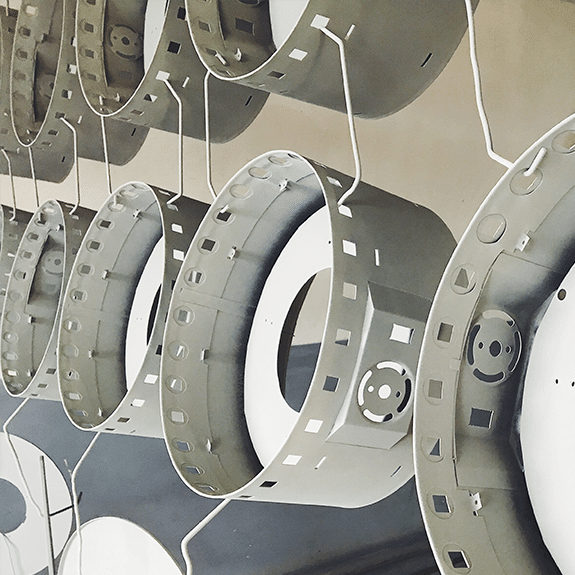

Metal Finishing

We offer a wide-range of chemical processes for multiple types of steel and aluminum.

- Fine Grain Zinc

- Heavy Grain Zinc

- Manganese Phosphate

- Iron Phosphate

- Black Oxide

- Passivation

- Chem Film (Conversion Coating)

- Ultra Sonic Cleaning

- Vapor Degreasing

- Pickle & Oil

- Grit Blasting

Additional Services

Sub Source provides several additional and value-added services to streamline your secondary service needs. If you are looking for a service that is not provided on the website, please give us a call to see if we can accommodate your requirements.

Uses a heat-cleaning oven to remove materials such as oil, paint, plastic and varnish from metal products

- Steam Cleaning

- Pressure Washing

Determines if a part is clean and free from contaminants

We offer local and surrounding area deliveries, including Chicago.